How Rubber Cables Improve Flexibility And Durability?

In the electrical industry, the choice of cables plays a critical role in determining the efficiency and reliability of a system. Rubber cables have gained popularity due to their exceptional flexibility, durability, and resistance to harsh environments. Whether used in industrial applications, construction sites, or outdoor settings, rubber cables offer advantages that standard PVC cables may lack. This article explores the benefits of rubber cables, their applications, and why sourcing them from reputable rubber cable suppliers is crucial for optimal performance.

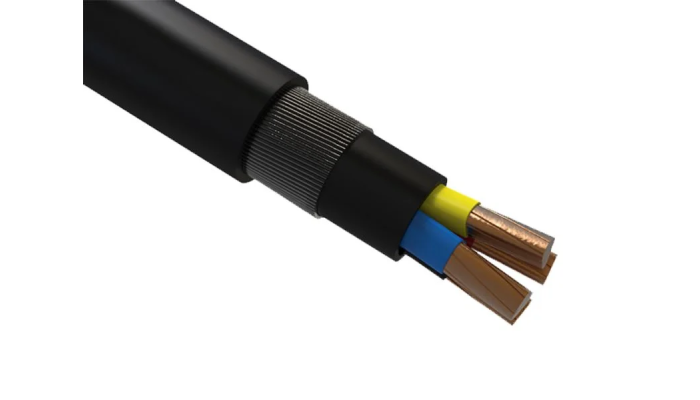

What Are Rubber Cables?

Rubber cable suppliers are electrical cables with an insulation and outer sheath made from high-quality rubber compounds such as ethylene propylene rubber (EPR), chloroprene rubber (CR), or natural rubber. Unlike standard PVC cables, rubber cables provide enhanced resistance to extreme temperatures, moisture, and mechanical stress, making them suitable for demanding environments.

Key Benefits of Rubber Cables

Superior Flexibility

One of the primary advantages of rubber cables is their outstanding flexibility. These cables remain pliable even in extreme weather conditions, which is essential for applications requiring frequent movement, such as in industrial machinery and portable equipment. The flexibility of rubber cables reduces the risk of internal wire breakage and extends their lifespan.

Enhanced Durability

Rubber cables are designed to withstand harsh environmental conditions, including exposure to chemicals, oils, and UV radiation. Their robust construction ensures they can endure mechanical stress, making them ideal for heavy-duty applications such as mining, marine operations, and manufacturing industries.

Temperature Resistance

Rubber cables exhibit excellent performance in both high and low temperatures. Unlike PVC cables that become brittle in cold climates, rubber cables maintain their integrity and remain functional in extreme conditions. This makes them a preferred choice for outdoor installations and industries exposed to high heat or freezing temperatures.

Water and Moisture Resistance

Rubber insulation provides superior resistance to moisture, making these cables ideal for use in wet and damp environments. Industries such as marine, construction, and underground cabling benefit significantly from the waterproof properties of rubber cables, ensuring safe and reliable electrical connections.

Abrasion and Impact Resistance

Industrial settings often involve rough handling of cables, which can lead to wear and tear. Rubber cables offer high resistance to abrasions and mechanical impacts, reducing the risk of damage and minimizing maintenance costs.

Common Applications of Rubber Cables

Industrial Machinery

Factories and manufacturing plants use rubber cables to connect heavy-duty machinery. Their durability ensures an uninterrupted power supply and reduces downtime caused by cable failures.

Mining Operations

The mining industry requires cables that can withstand tough conditions, including exposure to dust, moisture, and mechanical stress. Rubber cables are highly preferred in mining operations due to their rugged construction and resistance to harsh elements.

Marine and Offshore Applications

Ships, docks, and offshore platforms rely on rubber cables for power distribution and communication. Their resistance to saltwater corrosion and moisture makes them ideal for marine environments.

Construction Sites

Temporary power distribution at construction sites demands cables that are flexible, durable, and resistant to external damage. Rubber cables provide the perfect solution for handling power supply needs at dynamic and demanding worksites.

Outdoor and Agricultural Use

Agricultural equipment, irrigation systems, and outdoor power tools benefit from rubber cables due to their weatherproof properties. These cables ensure reliable performance in fields, greenhouses, and remote agricultural areas.

How to Choose the Right Rubber Cable Supplier?

Look for Quality Certifications

Reputable rubber cable suppliers should adhere to industry standards and certifications such as ISO, IEC, or CE compliance. These certifications ensure that the cables meet safety and performance requirements.

Assess Product Range and Customization Options

A reliable supplier should offer a wide range of rubber cables suitable for different applications. Additionally, some suppliers provide customization services to tailor cables to specific industrial needs.

Check Customer Reviews and Industry Reputation

Customer feedback and supplier reputation play a crucial role in determining the reliability of a supplier. Checking online reviews and industry recommendations can help identify trustworthy suppliers.

Consider Pricing and Supply Chain Efficiency

While quality should never be compromised, pricing also matters. A good supplier provides cost-effective solutions without sacrificing quality. Additionally, ensure they have an efficient supply chain to prevent project delays due to shortages.

Conclusion

Rubber cables offer unmatched flexibility, durability, and resistance to environmental factors, making them an excellent choice for various industries. From industrial machinery to marine and construction applications, their superior properties make them indispensable in demanding environments. Choosing the right rubber cable suppliers ensures that you get high-quality cables that meet safety and performance standards. Whether you need cables for heavy-duty applications or general-purpose use, investing in rubber cables is a long-term solution for reliability and efficiency.

Burton Moreno, a passionate blog writer residing in the United States, blends his love for business, technology, and travel into captivating content. Based in a vibrant state, Burton brings a unique perspective to his readers, offering insights and experiences that inspire exploration and innovation.